Marine grade birch plywood is a high-performance material that stands out in many applications, particularly for industries requiring robust durability in challenging environments. Unlike standard plywood options, Marine grade plywood is manufactured to meet higher standards, particularly in terms of moisture resistance, strength, and longevity. This makes it ideal for use in areas where exposure to moisture or harsh conditions is common, such as boat building, van flooring, or construction projects near water. The difference between marine-grade plywood and other types lies not just in its resistance to moisture but also in its overall quality and the nature of its core composition.

One of the key differentiators is the glue used in Marine grade birch plywood. This plywood is bonded using water-resistant phenolic resins, which give it superior durability when exposed to moisture compared to the urea-formaldehyde adhesives often used in other types of plywood. These resins ensure that the layers remain intact and prevent delamination, even when subjected to water over time. This quality makes it a go-to choice for environments where long-term exposure to moisture is unavoidable.

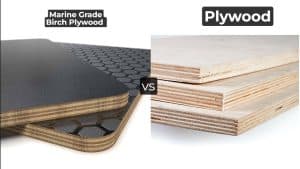

Another important factor is the grading of the wood itself. Marine grade plywood, particularly birch varieties, is manufactured with fewer defects and voids between layers. This gives the material greater uniformity in structure and strength, which is essential in applications where stability is a priority. In comparison, standard plywood often contains more knots, gaps, and irregularities within its layers. These defects can compromise the structural integrity of the plywood, particularly in demanding environments where pressure and moisture are constant factors. For instance, van flooring often sees heavy use, and the durability of marine grade plywood helps it withstand weight and movement better over time.

The finish of Marine grade birch plywood is also a point of distinction. The smooth, high-quality surface of this plywood is easy to clean and maintain, unlike standard plywood, which may require additional sanding or finishing. For industries like van lining, where aesthetics and functionality both play a role, this surface finish offers a dual advantage. Not only does it provide a professional appearance, but it also reduces the time and cost involved in preparing and maintaining the surfaces. Additionally, the use of marine-grade plywood helps in reducing wear and tear on the floor, ensuring that it looks and functions well for longer periods.

One common question when choosing between marine-grade birch plywood and other types is whether the extra cost is justified. In many cases, the answer is yes. While the upfront cost of marine-grade plywood is higher than that of general-use plywood, the long-term savings in maintenance, repair, and replacement often outweigh the initial expense. This is particularly true for businesses like delivery services or cargo van operators, where downtime due to maintenance can lead to significant operational disruptions. Using higher-quality materials like marine-grade birch plywood can help minimize these issues.

Another benefit of marine grade birch plywood is its sustainability. Birch is a renewable resource, and when sourced responsibly, it contributes to a smaller environmental footprint than some other types of plywood made from less renewable or more resource-intensive species. Marine grade plywood is often manufactured to comply with strict environmental standards, making it a better option for eco-conscious businesses. At Sydney Van Lining, we ensure that our marine-grade birch plywood meets these standards, ensuring both durability and environmental responsibility in our products.

In contrast to other plywood types, such as softwood or interior plywood, marine-grade birch plywood offers superior structural performance. Softwood plywood, while lighter and cheaper, tends to warp or degrade more quickly when exposed to moisture. It may work for interior applications but is not suited for outdoor or high-moisture environments. Likewise, interior plywood, often used for cabinetry or furniture, lacks the water-resistant glue and durability required for heavy-duty uses like van flooring. While these options may be more affordable initially, they are not as cost-effective in the long run due to their lower performance in demanding conditions.

In conclusion, Marine grade birch plywood sets itself apart from other types of plywood due to its water resistance, strength, and overall durability. Its smooth finish, fewer voids, and use of superior adhesives make it an excellent choice for industries and applications where quality and longevity are critical. While other plywood options may be more affordable upfront, Marine grade birch plywood offers better long-term value, especially in environments exposed to moisture or heavy use. Whether you’re outfitting a van for heavy-duty applications or working on a project requiring high-performance materials, marine-grade birch plywood is worth the investment.

For more information on how Sydney Van Lining uses Marine grade birch plywood in our van lining Products, you can visit our website to explore our product range.